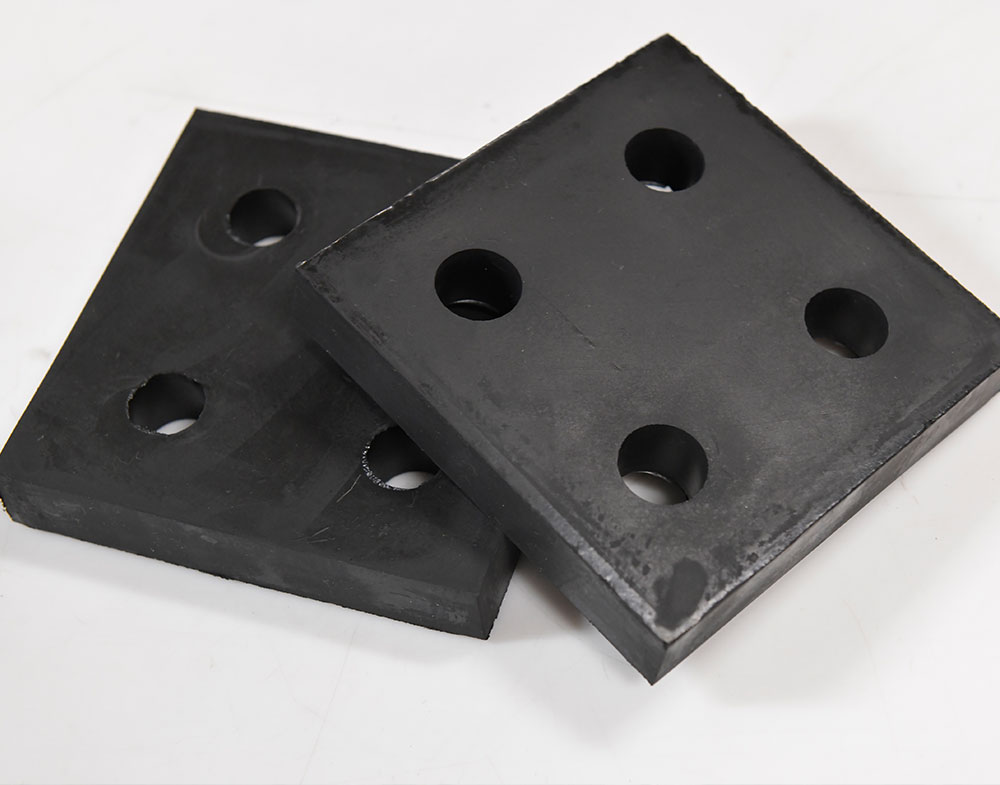

Rubber Molding and Rubber Molding to Substrates

MPS Manufacturing is a leading manufacturer of top-quality custom molded rubber products for a variety of industriesRubber Molding

We are rubber molding experts from equipment and mold design and fabrication to production. With advanced technology, proficiency in the industry, and agility for large and small custom projects, we are the superior partner for your next rubber molding project.

- Semi-automated Transfer/Compression, Vacuum, and Non-Vacuum Molding Presses

- Short and long run production using customers’ existing tooling or our own custom-built, low-cost tooling

- In-house mold design

- Mold troubleshooting and customization

- Expertise in process results in better running mold and less post-molding processing

Rubber Molding to Substrates

We offer rubber molding to substrates, providing a superior bond between a rubber part and a rigid component, completed during the molding process. Consistency and efficiency are top priorities to help reduce scrap and keep costs low.

- Combine flexibility of rubber with strength of rigid component

- Bonding to substrate during molding process

- Reduces assembly time and provides superior adhesion

Products:

- Grommets & Bumpers

- Bushings

- Mounts (Isolation)

- Mounts (Performance)

- Seals & Gaskets

- Protective Caps & Plugs

- Oil & Gas

- Suspension Components

Materials:

- Natural Rubber

- Neoprene

- Silicone/Flouro

- SBR

- EPDM

- Nitrile

- Viton (FKM)

- HNBR

- NBR

- Millable Urethane

The MPS Advantage:

- LEAN manufacturing processes for cost savings and reduced waste

- Complete traceability from raw material to finished product

- Meet ASTM and MIL-R specifications

- Diversity in design and production

- Prototype to production quantities

- Short runs, fast runs

- Scalability

- Made in the USA

Industries Served