Design and Fabrication Machining

MPS Manufacturing is a superior partner, offering in-house mold and equipment design and fabricationCustom In-House Mold Design and Fabrication

We are experts in the rubber molding process from beginning to end and provide highly accurate mold design and fabrication for custom parts. Our oversight of the entire process allows us to produce the best performing molds that reduce post-mold processing.

- Concept to final product

- Accurate, durable molds

- Highly accurate machined or turned components

- Types:

- Compression Tooling

- Transfer Tooling

- Injection Tooling

- Prototype Tooling

- Cold Runner System

- Cold Pot Transfer

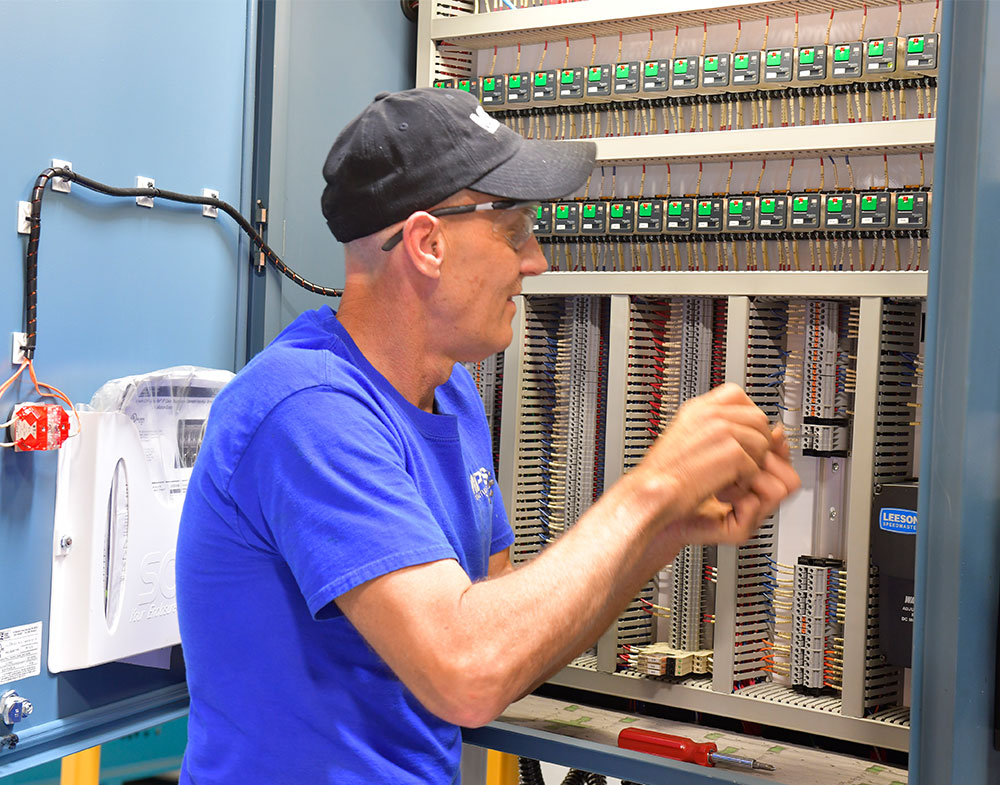

Custom In-house Equipment and Electrical Panel Building

With over 40 combined years of experience in the rubber industry, we have a comprehensive understanding of the equipment and processes required for the optimal result. Our in-house equipment and electrical panel building provides cost savings and greater efficiency.

- Custom-built equipment for maximum performance

- Design and fabrication expertise

- Complete process control

Software:

- Solidworks to Camm Software

- Ability to read Unigraphics, .iges,step, parasolid, and many more industry-standard files

The MPS Advantage:

- 40 years of experience in mold and equipment design for the rubber industry

- Custom, low-cost domestic tooling and equipment

- Strict quality control

- Scalability

- Made in the USA

Start a Custom Project

Industries Served